Company Foundation:

“PUIG FAIRINGS”

In the garage of their house in Granollers, Spain, the brothers Josep and Jaume Puig founded the company “Carenados Puig” as a result of their motorcyle passion, only 100m2 that saw the birth of a dream, making motorcycle fairings.

The two founders were Derbi workers, and they materialized their dreams by turning their passion into their work.

On the left of the image we see Josep Puig, who is in charge of the commercial part of the company, and on the right Jaume Puig, responsible for the technical part and the design of the pieces.

Photographed on a competition Montesa 250cc with Puig fairing and screen in Granollers, very close to where the company’s headquarters are currently located.

New products

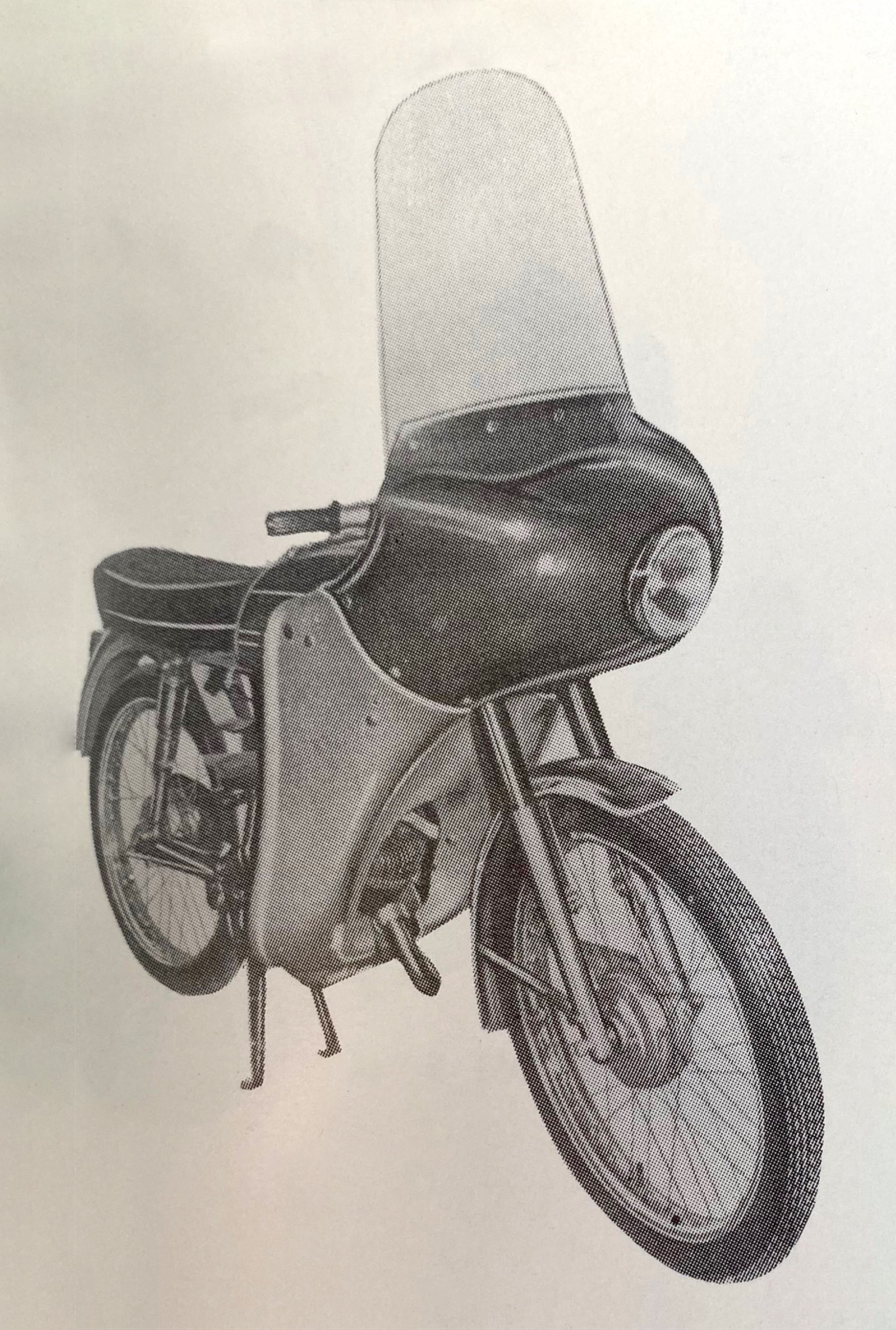

TOURING FAIRING for DERBI 49CC

“LEG SHIELD” for DERBI 49CC

PRODUCTION PHASES

1. Design and prototypes

2. Molds

3. Paint the mold with gelcoat

4. Layering of Polyester fiber

5. Demould and polish --- Finished part

EXPANSION OF THE FACILITIES WITH THE NEW SECTION OF POLITÉ SHEET BLOW MOLDING AND LAMINATING

A new blow molding section is commissioned to serve the Puch of Gijón brand and the sheet extrusion machine is used to produce the thermoformed semi-fairings and windshields for the Derbi and Vespa.

NUMERICAL CONTROL INCORPORATION

First 5-Axis robot.

The manufacture of polyester fiber is a very traditional process that does not allow meeting the growing demand and it is decided to promote thermoforming and pressing. More industrial processes to be able to manufacture more standardized parts and meet demand.

The production of fairings in polyester fiber is abandoned, and focuses on the design and manufacture of screens in acrylic material.

THE ORIGINAL REPLICA, TOURING AND DOUBLE BUBBLE SCREEN LINE OF PRODUCTION BEGINS AND MOVE TO A NEW WAREHOUSE

Puig also begins the manufacture of screens for motorcycles with original windshield. Puig screens are designed with small changes compared to the originals, in order to provide more style, protection, aggressiveness….

The design and production section moves to the new headquarters in the Can Castells Industrial area in Canovelles, Spain, the 1000 square meter warehouse is adjacent to the blow molding section.

Launch of our B2B website, pioneer in our sector. Huge step to improve our relation between our customers and our internal processes.

Introducing the virtual wind tunnel. An essential tool used to design all our products, finding shapes that combine best aerodynamics with better wind-protection.

EXPANSION TO THE USA – PUIG USA Inc

New distribution warehouse.

With the firm desire to open Puig brand to the American and South American markets by offering great service and competitive delivery times, a new headquarters is opened in Orlando (Florida) from where Puig products can be shipped to these markets.

The important increase on sales has pushed us forward on the fabrication section where a large investment has been made to automate part of the production, offering not only an improvement on quantity but also on quality.

AUTO THERMOFORMING PROCESS

Incorporation of a fully automated thermoforming machine.

Our website uses cookies to offer you a better service.

By selecting your country we can offer you a more personalized view of our product.